Synthesis and Characterization of Nanocomposites for 3D Printed RF Devices

Jing Wang, Associate Professor

Department of Electrical Engineering

University of South Florida, Tampa, Florida 33620

jingw@usf.edu;813.974.6011

Overview of the Wang research group: The Wang group works primarily in the area of functional nanomaterials, nanotechnologies, micromachined sensors and transducers, RF/microwave devices and microsystems. In the field of nanotechnologies, his group developed novel techniques for formation of nano-scale devices and nanostructured materials with critical feature sizes down sub-100nm. Examples include first-reported growth of densely-packed ZnO nanowires over the sidewall of deep trenches and nanomanufacturing of quantum tunneling diodes with junctions of 100nm 100nm. Another area is to develop micromachined piezoelectric or capacitive transducers for sensing, low power wireless telemetry, and signal processing applications. Recently, his group has developed resonant mass sensors with resolution down to attogram (1E-18g), which will to be integrated with readout circuits for future point-of-care apparatus. Another key focus is in the area of synthesis, characterization and implementation of functional nanomaterials into 3D printable RF and flexible electronics, such as antennas, waveguides, transmission lines, filters, couplers, etc. We are currently investigating polymer-ceramic nanocomposites with evenly dispersed high permeability or high permittivity nano-fillers for RF device miniaturization by reducing electromagnetic wavelength.

Overview of the Wang research group: The Wang group works primarily in the area of functional nanomaterials, nanotechnologies, micromachined sensors and transducers, RF/microwave devices and microsystems. In the field of nanotechnologies, his group developed novel techniques for formation of nano-scale devices and nanostructured materials with critical feature sizes down sub-100nm. Examples include first-reported growth of densely-packed ZnO nanowires over the sidewall of deep trenches and nanomanufacturing of quantum tunneling diodes with junctions of 100nm 100nm. Another area is to develop micromachined piezoelectric or capacitive transducers for sensing, low power wireless telemetry, and signal processing applications. Recently, his group has developed resonant mass sensors with resolution down to attogram (1E-18g), which will to be integrated with readout circuits for future point-of-care apparatus. Another key focus is in the area of synthesis, characterization and implementation of functional nanomaterials into 3D printable RF and flexible electronics, such as antennas, waveguides, transmission lines, filters, couplers, etc. We are currently investigating polymer-ceramic nanocomposites with evenly dispersed high permeability or high permittivity nano-fillers for RF device miniaturization by reducing electromagnetic wavelength.

Teacher Project: Synthesis and Characterization of 3D Printable Polymer-Ceramic Nanocomposite Materials

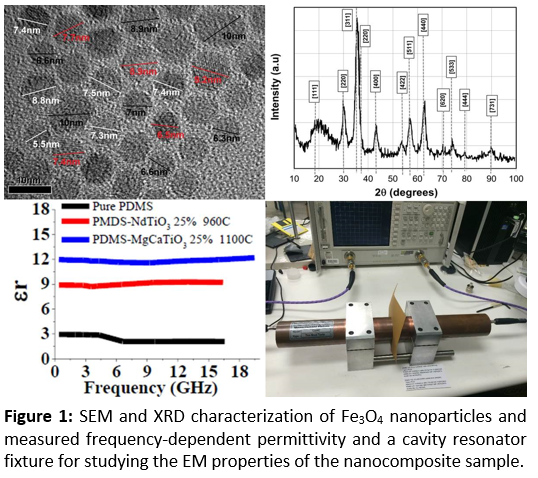

The goal of this project for the teacher is to synthesize core-shell or surfactant-coated magnetic or high-k dielectric nanoparticles and use them as homogenously dispersed nano-fillers in a variety of thermoset or UV-cured polymer matrices. In term of synthesis route, both chemical precipitation and surfactant-assisted ball milling will be jointly investigated, with particular emphasis on the ability to achieve tight nanoparticle size distribution while avoiding particle-to-particle agglomeration that tends to compromise the unique low-loss properties. The teacher will use material metrology techniques such as x-ray diffraction, transmission and scanning electron microscopy to study the morphology and crystallography properties or the synthesized high-permeability or high-k nanoparticles. These materials will then be employed as nano-fillers, which will be homogenously dispersed into a variety of low-loss polymer matrices (e.g., PDMS, ABS, ULTEM, Cyclic olefin copolymer, etc.) by the state-of-the-art techniques such as solution blending and melt blending. The RF and electromagnetic properties of the nanocomposite materials will be studied through preparation of the hot compression molded specimens, which will be characterized by using resonator cavity or coaxial fixture based testers to reveal their dielectric permittivity, magnetic permeability and loss properties over frequencies ranging from DC to 20GHz. As an ultimate goal, the newly developed nanocomposite materials will be utilized as the "ink" for printing a demo device, such as an antenna, by using a state-of-the-art 3D printer at the Nanotechnology Research and Education Center (NREC) at USF.

All facilities will be in-place for the teacher to start the project immediately. The first few days will be spent on re-reading a few relevant journal articles (which will be provided ahead of time), training on the synthesis method, learning the use of laboratory equipment, and discussions with Professor Wang and a couple of graduate students, who will work alongside the teacher on related projects. Depending upon progress, co-authorship of a conference presentation and a journal article are possible for the teacher, from this project.

- 1. Upconversion Photocatalysis for Energy and Environmental Applications

- 2. Sorption of Organic Vapors by Polymers using a Quartz Crystal Microbalance

- 3. Effective Deposition and Spreading of Powder Layers for 3D Printing

- 4. Synthesis and Characterization of Structured Nanomaterials for Energy Applications

- 5. Syntheses and Characterizations of Catalytically Active Porous Metal-Organic Frameworks (MOFs)

- 6. Microfluidic Filtration of Circulating Tumor Cells

- 7. Simulation and Rational Design of Metal-Organic Materials

- 8. Composition of Organic and Inorganic Polymeric Nanofibers for Filtering, Tissue Scaffolding, Wavelength Reflecting, and Self-healing Functionalities

- 9. Dynamic Tissue Cultures for Cell Printing

- 10. Synthesis and Characterization of Nanocomposites for 3D Printed RF Devices